Welding Lab

Teaching students the art of welding.

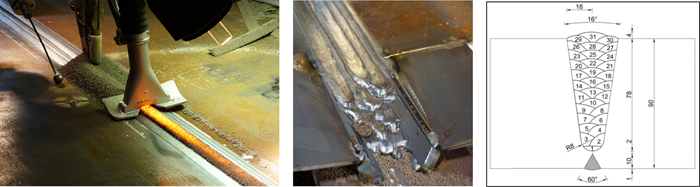

Welding Residual Stresses in Offshore Steel Structures

The objectives of this research is to investigate, determine and compare the welding residual stresses in supersize (XXL) monopile cans with large wall thicknesses from 50 mm and up to 120 mm welded by two different welding methods; (i) submerged arc-welding and (ii) laser-hybrid welding. The fatigue strength in such structures is particularly influenced by the residual stresses at the welds. The residual stresses in these structures are not yet fully understood, leading to a reduced fatigue strength and thus to larger and more expensive structures. By investigating the welding residual stresses and welding methods by means of computational welding mechanics, experiments and in accordance with existing production procedures, an optimization in regard of fatigue design is expected, leading to a much more efficient and improved design.

The research within the field of welding residual stresses is important for the industry to better understand the various behaviors of the steel components when size of welds are rapidly increasing and to be able to follow the demands from steel fabricators when deeper foundations are needed by design. The research will definitely benefit the offshore industry by leading to a more efficient and improved design intended to be included in present norms and standards. Further it will optimize the correlation between numerical simulations and physical models.